No products in the cart.

It's a never-ending story.

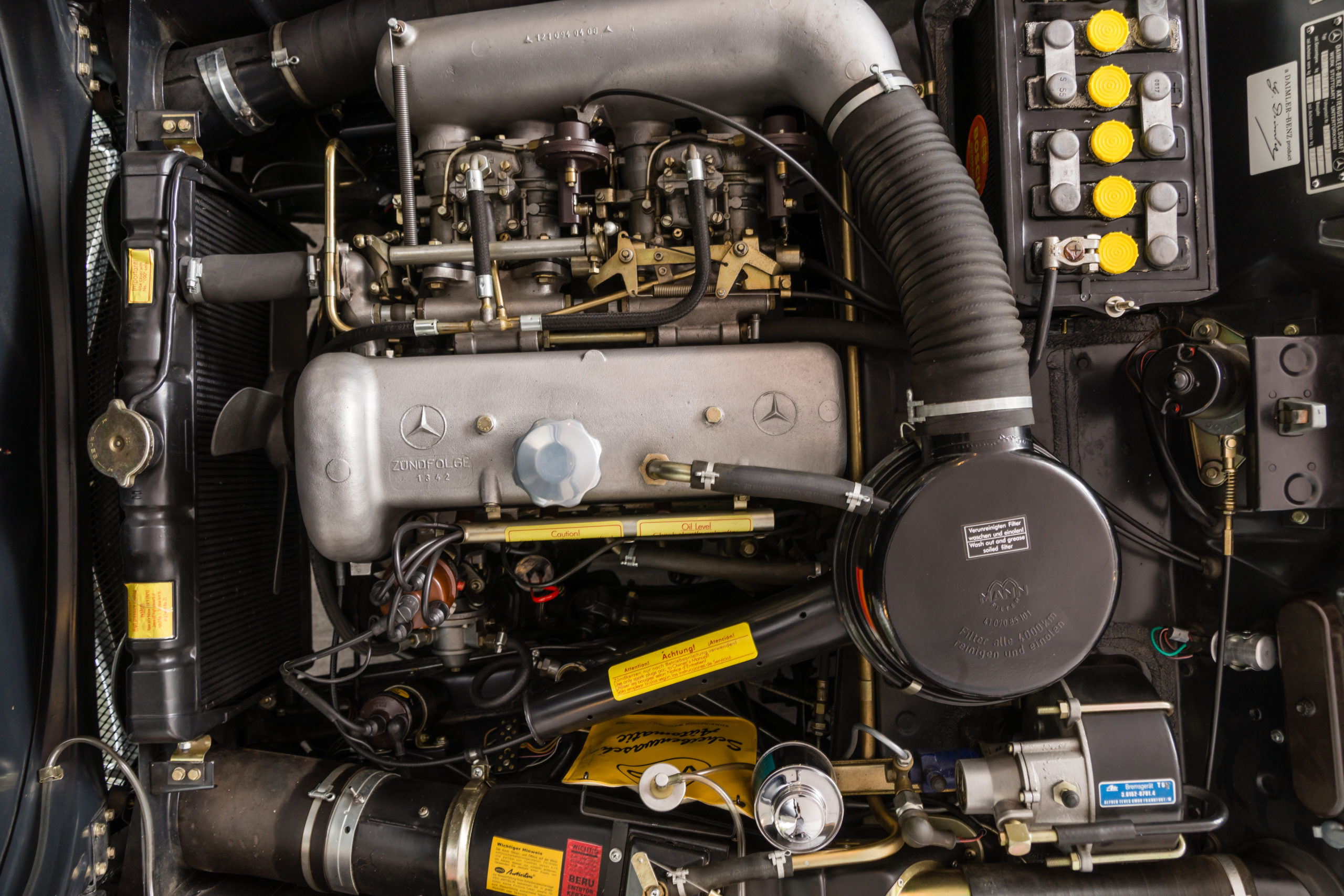

Carburettor system, constant air leaks, rough-running engine, idling speed too high, juddering when accelerating, engine cutting out when under load and dying when braking.

These are all typical signs of an erratic fuel/air mixture. If the wrong air is drawn in – no matter where it's from – the fuel-air mixture in the combustion chamber becomes too lean and causes this problem.

A common fix is to reattach the carburettor but this doesn't always get the engine running smoothly. If the carburettors have been fitted to the vehicle for a long time, air intake leaks can be caused, for example, by a worn butterfly valve. You can carry out the following preliminary test:

Any owner can check the operation of their carburettor for themselves by following these guidelines.

Depending on the location of the leak, we can help you with the following:

If there is a leak between the intake manifold and the cylinder head, the manifold may be tightened using a straight 14 mm ring spanner.

Proceed as follows:

Unscrew the fuel line at the carburettor, unscrew the vacuum hose at the manifold. Place the ring spanner over the elbow nut and tighten. Remove the spanner from the nut, turn it 180 degrees, put it back on the nut and tighten again. The elbow nuts must be tight. You could slide a short piece of pipe over the spanner and tighten again. Inspect the washers (5mm thick) on the brass nuts that fix the intake and exhaust manifolds against the cylinder head. If the washers are at an angle, it means that vibration has already worn down the intake manifold to such an extent that it will no longer seal even if it is tightened up. In most cases, the tolerances of the intake manifold where it attaches to the cylinder head will no longer be correct. If this is the case, the intake manifold will have to be replaced, refurbished or overhauled. We will be happy to take care of this for you. You can send the parts to us by post or bring the vehicle along to our workshop.

If there is a leak between the carburettor and the intake manifold, you will need to replace the gaskets. To do this, the air intake pipe and the carburettor have to be removed and reinstalled.

To set the correct clearance for the carburettor gaskets, spacers are fitted to the carburettor flange, with 8mm washers between the carburettor housing and the rubber flange to prevent the spacers from damaging the joints in the carburettor housings. It is also common for the spacers to work through the steel washers. This causes the carburettor to loosen and is another possible source of leaks.

We have a solution for this too: bushes with a collar machined from a single block of steel. We also offer a complete improved carburettor mounting kit with mounting brackets.

We have developed a different method of attaching the carburettor. Experience has shown us that the more accurately you fit the carburettor, the longer the rubber flanges last and the less likelihood there is of air leaks. We replace the usual spacers with our one-piece flanged bushes.

We also fabricate special attachment brackets. The benefit of these brackets is that they are mounted directly to the rubber washers, which allows the carburettor to be retightening later from below without having to undo the air intake pipe.